Dental Sintering Furnace

After dental sintering furnace has been machined into a crown, bridge, framework, or other restoration, dental sintering furnaces are used to process it. These furnaces can reach the severe temperatures needed to sinter zirconia to its final hardness. The sintering process, which can include both pressure and heat, reduces porosity and improves density in ceramics like zirconia.

Zirconia shrinks significantly during the sintering process. It’s crucial to think about capacity, pre-programmed cycles, and automation capabilities when selecting a sintering furnace for your clinic or lab. Producing your own zirconia restorations is now faster and easier than ever due to sintering furnace.

The sintering procedure is what gives zirconia restorations their strength. Sintering is a thermal treatment that is widely used to augment a material’s strength and structural integrity.

To obtain sintered zirconia, the heat from the sintering furnace is transferred to the surface of the material and then thermally conducted to the core. A heating, sintering, and cooling phase are all part of the sintering process.

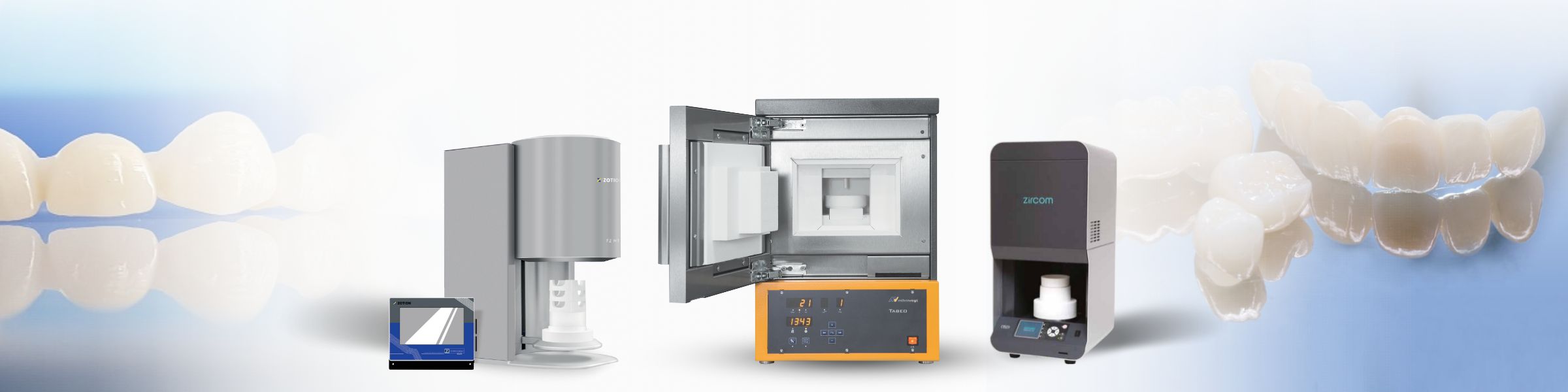

Unicorn DenMart has the Dental Zirconia Sintering Furnace from Mihmvogt Tabeo series, Germany that is ideal sintering furnace with heating element of molybdenum Disilicide and it can sinter up to 30 units in 1 tray.

Recent Blog

Enhancing Diagnostic Accuracy with Advanced Imaging

Advancing Dentistry Through Cutting-Edge Imaging Techniques In the realm of...

Read MoreDental CAD Software: The Future of Design and Restorations

Navigating the Digital Revolution in Dentistry: The Rise of Dental...

Read MoreThe Evolution of Dental Impression Systems: From Analog to Digital

The Evolution of Dental Impression Systems: From Analog to Digital...

Read MoreDental Milling Machines: The Future of In-House Restorations

The Evolution of Dental Restoration Methods The journey of dental...

Read More